Intelligent Delivery-as-a-Service

Deliver on your promises, and then some

Improve customer satisfaction, reduce inventory leakage and lower costs; all thanks to Intelligent Delivery-as-a-Service

An uncomfortable truth

Let’s face it, the promise of an automated service parts delivery process hasn’t come to pass. We may be able to connect order management and resource planning systems but we’re still struggling with the same old issues:

Broken SLAs

Parts are arriving late or failing to arrive at all.

High transportation costs

Stringent SLAs that include 2-4 hour delivery windows means spending on costly near-instant delivery services.

High inventory costs

A lack of inventory visibility means we’re spending on new parts while equipment gathers dust in warehouses and depots.

Last mile blindness

An inability to track and control deliveries during the final stage of the process

Why automation fails

The reality is that the delivery process resists automation. It’s a complex process that involves numerous parties from different companies. And a lot can go wrong. Human error is common, traffic jams more so. No IT system can account for this level of complexity and unpredictability.

Our solution – Intelligent Delivery-as-a-service

Intelligent Delivery-As-A-Service is our solution to these problems. It’s a managed service powered by predictive analytics. We enhance automated processes by applying our unique brand of delivery intelligence at critical junctures. And we don’t just keep the engine ticking over. We refine and optimize your processes over time. This is all thanks to our proprietary platform – OnProcess AgoraTM.

Key service features

Order desk management

Omnichannel contact center orchestration.

System integration management

Connecting CRMs, ERPs and third party systems (e.g. logistics consoles).

Predictive analytics

Conducted and managed through OnProcess Agora.

Proactive process optimization

We transform your processes to take proactive rather than reactive action.

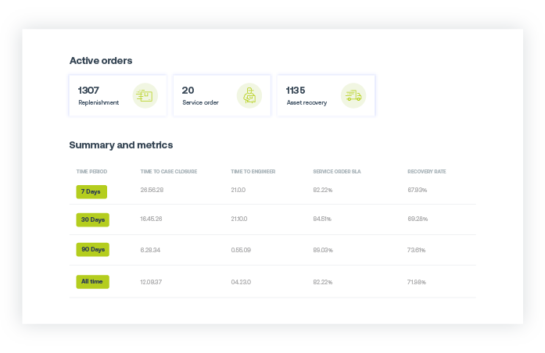

End-to-end reporting

Accessible via customizable dashboards

Custom algorithms and predictive intelligence

Agora allows us to analyze millions of data points captured over decades of deliveries. We apply our custom algorithms to turn this insight into predictive intelligence that guides us and allows us to make better decisions in real-time.

For example, we can predict:

Where parts will be at any given time – in transit, with customers or in warehouses – and if wrong or excess parts are ordered

The likelihood of outbound order failure, service delivery failure or install failure

Early life customer churn on new installations

The volume of No Fault Found (NFF) or No Trouble Found (NTF) parts recovered over a set period of time

Warranty fraud events

The benefits

This insight allows us to take proactive action before and during the delivery process so that we can solve problems, avoid wastage and maximize efficiency on your behalf. This means you:

Deliver a better standard of service

by honoring delivery promises and meeting or exceeding SLAs.

Reduce transportation costs

as you can pre-empt demand and allocate resources accordingly, ahead of time.

Limit inventory spending

with greater oversight over supply, demand and recovery you reduce spending on excessive inventory.

At the same time, your business becomes more sustainable. Limit truck rolls and reuse your existing inventory and you can dramatically reduce your carbon footprint overnight.

Optimizing the Plan-Deliver-Recover lifecycle

Delivery is just one phase of the after-sales lifecycle. Just as important are the Plan and Recover phases. That’s why we apply our learnings from each process across the entire lifecycle. So if we can see that planners are needlessly ordering parts that are due to be recovered then we can act early to root out unnecessary spending. This is how we help our clients make the biggest savings.

Intelligent Delivery-as-a-Service in numbers

20+

years’ experience

24m

The number of transport events we manage per year

10m

The number of outbound orders we manage per year in North America alone