Business schools have long touted that complexity and uncertainty is the new business normal, with the last year-and-a-half highlighting in stark reality that volatility and ambiguity is something with which we must learn to deal. VUCA as it is known[1] represents a business environment that is more uncertain and unpredictable than ever before. Increasing costs of fuel, raw materials, and commodity prices, higher wages, and sophisticated supply chains all contribute to complexity levels and a fragility that are difficult to maintain. Layer that with increased regulations, environmental goals and pressures, and increased global competition, and it becomes too much for many.

Companies that rely on their traditional supply chain processes and entirely manual practices lose their ability to adapt and become unable to see and manage across the new levels of complexity. Then they end up falling even further behind.

The only way that companies will survive is to turn to smart digital technologies that will help them cut through the complexity, see across the vast lakes of data, and delve deep into the information and processes to find better ways of running.

A recent McKinsey study revealed that the average supply chain has a digitization level of 43 percent, the lowest of five business areas that were examined. The same McKinsey research calculated that companies that aggressively digitize their post-sale service supply chains can expect an efficiency boost of around 65%-70% — the largest consistent increase from digitizing any part of the supply chain[2].

What is Supply Chain Digital Transformation?

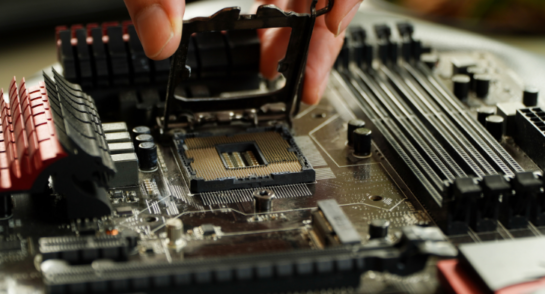

At OnProcess we define it as leveraging “Industry 4.0” technologies such as internet-of-things (IoT), robotics, virtual reality, artificial intelligence and in particular data, and combining them with new digital communication channels to intelligently automate and augment operations, and derive insights into completely new ways of working that deliver high impact and benefit to the customer.

The core to this is data, and therein lies the challenge too, because the reality is that many supply chain and service supply-chain functions work in ‘data silos’. Applications don’t talk to each other, data is not properly shared, and cross-functional visibility is not normal. The result is that when a crisis hits – such as the Ever Given Ship that was stuck in the Suez Canal[3] in March 2021 for more than two weeks – it catalyzes supply chain nightmares for many because their lack of full visibility does not allow them to re-adjust processes and mitigate their risks.

With 20+ years of experience in the post-sale service supply chain our approach is one of building a standardized data-layer that pulls together the otherwise siloed data, cleans it and structures it around both the service part and the customer and the post-sales experience that they should have. By joining these siloes together in a circular fashion, it allows for example Planners to have full visibility of recovered assets, potentially saving on new material buying, or dispatch professionals having before-it-happens visibility of soon-to-fail parts, allowing for a more proactive dispatch of spare parts.

The benefits of a digital supply chain are hard to ignore

Transforming and digitizing a company’s post-sale service supply chain empowers supply chain professionals to better plan, source, collaborate, execute, automate and leverage analytics, to not only ensure the product or part is efficiently managed but also that the customer receives the very best service experience in the process. The business impact and ROI fall into four key areas:

1. Efficiencies and Lower Costs

Throwing technology at a supply chain problem may not always be the right answer, when done intelligently it can have huge cost saving impact. From smarter inventory planning and parts scheduling, to increased ‘first-time’ right-time and fix rates, quicker dispatch times and seamless old-part and asset recovery rates; driving greater efficiencies, reducing errors and ultimately saving significant costs can be the immediate results of digitizing the supply chain.

2. Customer satisfaction and service-levels

From the moment the customer commits there is a level of expectation set. And in the post-sale and service supply chain there is an added level of urgency to “fix things” that is layered onto that expectation and experience. This is why visible efficiency, clear communication, error-free service-event resolution and keeping the customer’s experience front and center can be dramatically improved with the right application of digital tools and processes.

It can also lead to huge competitive advantage over rivals based on the satisfaction, reputation and customer loyalty the company gains as a result.

3. New Revenue Streams

Selling and supplying great products is one thing, but how you provide service around them is an entirely different matter. For many industries now, the revenues associated with post-sale service can outweigh the original product sale in value. Not surprising therefore that such focus is now put on how to ensure those service revenue streams are maximized and digital technologies can help to do that.

In the service supply chain for example, repairing products inevitably leads to the question of what to do with the old parts. Embedded warranty credits in those parts can represent unlocked value that would otherwise end up in landfill. Digital technologies can help identify individual warranty value of components in real-time at the point of service, then dynamically suggest what to do next with the part to efficiently realize that value.

4. Sustainability and the Circular Economy

Sustainability has become more than just a footnote on big companies’ websites, it has become a central strategy for most. It is no great surprise given that it is estimated that 90% of an organization’s environmental impact comes from it’s supply chain[4]. So how can it be improved? Well one way is to re-think the traditional linear “throw-away” supply chain model of Source-Manufacture-Distribute-Use-Discard and instead adopt a new “Circular Economy” model. It designs re-usability right into products and looks at keeping materials within the supply chain by re-purposing and re-using rather than buying new materials all the time. This puts an increased focus on old-product or asset recovery and the reverse-logistics involved in doing so. It is also helped by innovative new digital technologies that can efficiently predict when assets need recovering, when repairs are imminent as well as streamlining the complex data-flows and logistics between the processes.

Keep pace with technology

Technology advancements are happening at a breathtaking speed. Frankly it is hard to keep up, so choosing the right technology provider and advisor has never been so important. But the intelligent use of smart digital technologies, can have huge and positive impact on a company’s finances, customer experiences and environmental goals. Wholesale digital transformation and change can sometimes feel daunting, but it does not need to be. Quick wins in tactical areas will lead to further enthusiasm and appetite to do more.

It’s just a case of starting.

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.