In 2019, plastic waste was discovered in the deepest part of our oceans, the Mariana Trench, at a depth of 36,000 feet. It seems that almost no place on earth is free from the waste we produce.

The linear supply chains of the past, where parts were discarded to landfill, rivers and seas, are being ushered out in favor of more sustainable options. But discoveries like this prove we’re some way off true sustainability — and if something isn’t done, we’ll sink even further.

So, how can you start making a difference? Clearly, we urgently need to remove pollution from our ecosystems. But, equally importantly, we need to limit waste in the first place.

For businesses, the answer lies in building circular supply chains.

Circular service supply chains will be the norm sooner rather than later. But some industries need to take more immediate action to improve sustainability.

For example, the world’s healthcare industry makes up 4% of global CO2 emissions, while hospitals alone produce 13kg of medical equipment waste per bed per day — of which 15-25% is hazardous.

To avoid waste (both environmental and financial), businesses need to find ways to manage the lifecycle of products and parts for a more value-driven, efficient outcome.

But, what are circular supply chains? In this blog we’ll take you through everything you need to know, and then show you how you can start preparing for a more circular future.

What are circular supply chains?

A circular supply chain is a model that prioritizes product recovery and reuse over the traditional “take-make-waste” approach. Circular supply chain management is vital in contributing towards the circular economy.

The circular economy is “a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible”.

This is defined by three guiding principles: (1) To eliminate waste and pollution, (2) to circulate products and materials (at their highest value) for as long as possible, and (3) to regenerate nature and ecosystems.

Circular supply chain practices require a drastic shift from the traditional ‘build it, ship it, forget it’ model for businesses. They require new forms of collaboration and open sharing of data across different supply chain partners, as well as innovative processes that account for resource scarcity and environmental impact.

Unsurprisingly, some businesses find the prospect of switching to circular supply chain processes (also known as ‘closed loop supply chains’) daunting. Often, this is because they assume the price of implementation would be too expensive to justify — or, they may assume change is too difficult to implement. However, once processes are in place, a smart circular supply chain can drive a cleaner world and grow immense value for your business by:

- Lowering your cost of materials and production

- Improving your supply security through reclamation of materials

- Improving visibility of inventory flows to allow for better planning and reduced costs

- Reducing price variations and supplier risk from linear supply chains

- Providing additional customer value and a richer customer experience

- Combating climate change by helping you reach your sustainability goals

Building blocks for a circular service supply chain

Building circularity into your business model is not an overnight job. It requires a rethink of your value proposition and affects processes throughout your organization, all the way into your upstream and downstream supply chains.

There are plenty of factors your organization needs to consider in order to get your journey to sustainability on the right track. To successfully build a circular supply chain, you need:

- A fundamental shift in organizational thinking

- A solid data foundation and strategy

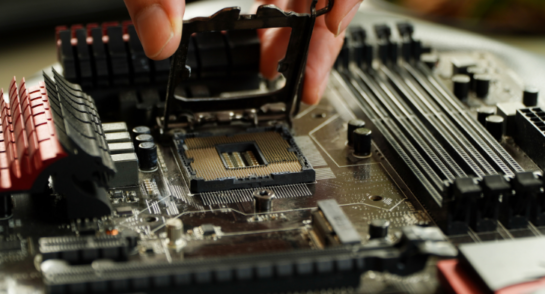

- Products re-designed not to be thrown away

- An efficient recovery process

- An intelligent AI and predictive analytics platform

Shift organizational thinking

Before you get started, make sure everyone in your business is on the same page when it comes to making changes for the purpose of sustainability.

This is a real dealbreaker. When you collaborate with others to work towards a common goal, you will naturally become more efficient and encounter fresh ideas.

Get your data foundations and strategy in order

For businesses to embrace the circular economy, they need insight into product flows so they can plan inventory levels and retrieve products at end of use. All too often, companies attempt to integrate circularity into their supply chains without access to the data they need to make it work. On top of this, in an attempt to push for circularity, the focus is too often on the forward logistics to ensure optimized product supply, manufacturing, and the delivery of ‘circular-ready products’. But none of this is relevant if there is no focus on the reverse logistics of getting those products back when no longer needed in the field.

Enter stage left – the service supply chain – which is critical to the circular economy, as it pulls data from every stage in the supply chain to identify how products can be maintained for longer, repaired, recovered, refurbished and reused.

So, it’s strange that the teams that manage planning and delivery of service parts are rarely completely in-sync with recovery processes. This can lead to them treating each stage of the process as unrelated — and as a result data is often siloed and not shared. That then leads to inefficient planning, limited understanding and ill-informed decision making — which equates not only to a high economic cost, but also reduced sustainability.

To build a solid data foundation and strategy for the circular economy, organizations need to address the integration of product data from all aspects of the service supply chain: planning, delivery and recovery.

When your data is aligned and your teams and partners are speaking the same language, it’s far easier to realize a collaborative, circular supply chain.

- Real-time product tracking ensures recovery trajectories are tailored and optimized for each unique case

- Unnecessary transportation is minimized, reducing emissions and increasing cost-effectiveness

- Effective decision making means no valuable materials or finite resources are wasted

- Field engineers can use up-to-date data to map the most efficient course of action to service parts on the spot

Build predictive recovery into your after-sales process

Traditional approaches to recovery processes like reverse logistics are usually informed by siloed data across the supply chain or outsourced to third parties.

Once your data foundation and strategy is in order, you can start to build an efficient and streamlined recovery process.

This is especially important when it comes to the actual recovery of assets. The ability to foresee exactly when and why a product will become faulty before it does means that the time it takes to recover the product from the customer will be drastically minimized.

Less time to recover means assets are tied up for less time and can be redeployed back to the market faster.

Leverage AI and predictive analytics to find the best next step

A strong data foundation is relatively useless without the ability to access and utilize it.

AI, AR and visualization tools are essential for mapping out the next best action in a circular supply chain and continuously improving planning for optimal inventory levels.

Data needs to be applied at the right time, to the right processes, in order to make a meaningful difference in decision making.

For example, if a piece of medical equipment is coming to the end of its lifecycle, historic data from throughout the product’s service supply chain can be used not only to accurately predict exactly when a problem may occur, but to inform field agents of problems in real-time or before anything even goes wrong. This will allow you to take the most efficient and sustainable next step every time, whether it’s to refurbish, maintain or recycle the product.

The road to the circular economy

Making sure your supply chain is ready to become circular isn’t just a step toward joining the critical push for a more sustainable world; it also opens the door to a variety of business benefits.

Besides the change management to get your organization ready and set up for lasting success in the circular economy, you need the right technology to: build an integrated and united data foundation, set up an efficient, informed recovery process, and bring it all together with an intelligent AI.

OnProcess provides technology and services to power the world’s circular service supply chains. With its proprietary platform OnProcess Agora(™) it allows data from otherwise siloed systems to be brought together to provide deep service insight and to drive intelligent and integrated circular service supply chain processes.

Want to learn more? Get in touch with us today for a free consultation and demo.

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.