Global supply chains are under pressure as never before. The interconnectivity, complexity, sensitivity, and vulnerability of supply chains are now fully exposed. Companies need to factor in new environmental regulations, trade agreement changes, supply and logistics constraints, security vulnerability, natural gas supply constraints, post pandemic economic factors, and labour shortfalls. Who would have thought that a reduction in global wind would have the recent impact on poultry availability on the supermarket shelves!

The focus, inevitably, is on the impact to the forward Supply Chain but the changes also have significant, if not greater, impact on the Reverse Supply Chain. The complexity of reverse supply chains results in even more challenges in dollar and carbon logistics costs, environmental compliance, and realisation of re-use and recycle rates versus landfill.

The importance of focusing on the end-to-end product lifecycle supply chain is key to circular success

It is no longer sufficient to establish and design manufacturing and product strategies that focus on improving carbon impact and reduce Supply Chain vulnerability and complexity for new products alone. These strategies need to be matched and complemented by a reverse supply chain eco-system that enables and realises the circular goal to “close the loop”.

There are three areas where forward and reverse supply chains need to complement and meet to realise the circular goal.

- Logistics: The environmental cost of logistics is, self-evidently, not recoverable so the challenge is in reducing the carbon footprint through consolidating returns, matching pick-up with drop-off logistic legs, using last mile EVs and implementing processes that enable re-use of recycled packaging. These are, in themselves, all easy concepts and ideas but require a coordinated, data driven approach to realise. Data driven logistics planning can address the gaps resulting from the forward and reverse logistics teams frequently being different and disconnected. This separation exaggerates the differing requirements between the needs of the drive to regionalise manufacturing and localise the services of repair, re-use and recycle in the reverse flow.

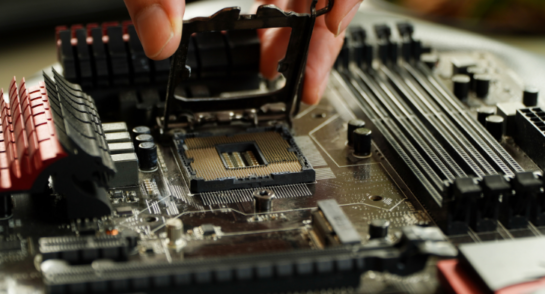

- Design: In designing a product the manufacturers must increasingly incorporate materials, from fabric to electronics, into the design that have better re-use properties whilst also recognising the need for ease of disassembly; emulating the earth’s closed system. However, without a complementary strategy that builds capabilities and a supply chain that can leverage the benefits from the circular design these design techniques are largely wasted. Development of the reverse supply chain requires a strong coordination and link with the design teams to continually drive the re-use and recycle features into future product designs.

- Environmental compliance: Finally, further localisation is driven by the legislation strictly governing the cross-border movement of waste protecting countries from becoming waste dumps. Movement of waste requires a multiplicity of license obtained through stringent inspection and bureaucratic demands on the carriers and handlers in the chain. Legislation (such as WEEE for electronics in the EU(1)) is becoming more wide spread and global. It promotes the localisation of re-use, repair and recycle with very strict targets being placed on the manufacturers. Managing the process and the reporting to comply and prove compliance is a complex task made easier by thoughtful product design and consolidating return and product information into a single data source/repository.

Reverse supply chain localisation simplifies and reduces the cost, complexity, carbon print and compliance risk of the reverse supply chain. However, combining and creating a harmonised approach in logistics, design and environmental compliance with a manufacturing and product strategy is the ultimate way to create a real and lasting positive circular impact.

Reference: https://eur-lex.europa.eu/legal-content/EN/LSU/?uri=CELEX:32012L0019

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.