Today is April 22nd – Earth Day[1] – a day that is observed around the world as a day to focus action on ensuring a sustainable planet. It was the day back in 2016 that the Paris Agreement was signed by 195 countries, and this year it is also the day that the US Biden administration has invited 40 world leaders to join a Leaders Summit on Climate[2]. What better day then to consider how truly transformational sustainability can be driven into the world’s supply chains.

The trouble with landfill

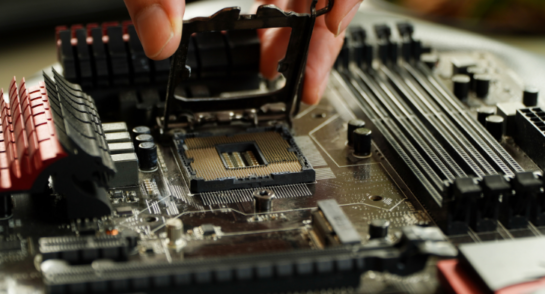

Every year, billions of dollars are lost in the disposal of raw materials and electronic waste. From silver to gold, copper to aluminium – it’s estimated that the raw materials from electronic waste (known as e-waste) in landfill total a global value of $57bn.[3]

In 2019 the world generated around 53.6 million metric tons of this e-waste, and it is growing at around 2.5 million tons a year – but the biggest waste of all is that much of it could have been reused.

This is indefensible because that represents parts, materials and products that could otherwise have been sold or put to use elsewhere. And given that every year we overshoot the day when humanity’s demand for resources exceeds what Earth can regenerate in that year[4] (Earth Overshoot Day was August 22nd in 2020), we simply must do something about it.

There are two questions we need to ask: How did we get to this point? And how can we quickly improve on such a global environmental and financial issue?

You only manage what you measure

Since the industrial revolution, manufacturing and associated supply-chains have evolved along a linear path that starts with extracting earth’s raw materials, making and distributing products from them, and throwing them away at their end of life. This take-make-dispose has prioritised economic growth through product and service delivery. This is partially due to the use of GDP as the main metric of socio-economic success – giving little airtime to data that points to environmental wellbeing.

Yet as people have learned more about the environmental cost of the take-make-dispose route, combined with new more demanding expectations around consumer service, and technology now providing vast sources of data intelligence, the opportunities of getting a greater enviro-economic balance have vastly improved.

This is no truer than in the supply chain.

Intelligent supply chains for the circular economy

Enter the idea of a new model of how we view our economies – the circular economy – the idea that products, parts and materials can be retained within our supply chains by recovering products and components, recycling them or their raw materials, and re-using with more care than defaulting to landfill. While technology vendors and manufacturers are still finding their way, some are beginning to see the significant financial, cultural, marketing and sustainability benefits of adopting circular supply chain principles.

In fact, with the right data and smarter decisions – enabled through technologies such as artificial intelligence or AI – supply chains and especially the post-sale service supply chain now have all kinds of opportunities to rethink the way materials and parts are sourced, distributed, used, maintained and upcycled.

For example, predicting when a business will require a new part before anything goes wrong, using augmented and artificial intelligence, can not only improve productivity and ‘up-time’, but also allow for better logistics management. When a part does fail, knowing how its components could be re-purposed, or where they could be sold for the optimum price and at the lowest transport cost can avoid it going to landfill and provide new revenue streams.

With good data and intelligent smart decisioning, the entire supply chain becomes an art of optimisation. Grabbing data at every opportunity and from every component and sensor -the internet of things – is making the circular economy a reality that every producer can exploit.

The circular economy is undoubtedly a big step for many, as doing it right will require some fundamental rethinking and redesign of products with re-use in mind, thought given to using recycled materials rather than raw, and how to economically extract from products not the ground. However, some smart steps can be taken now by focusing on how to efficiently recover assets and products from the field, return them for refurbishment or recycling, or at the least how to harvest critical materials before sending to waste.

We now have the means and the technology, and without doubt a very compelling reason that affects us all, to really rethink our service supply chains.

Why wouldn’t we now do something about it?

[1] https://www.earthday.org/

[2] https://www.whitehouse.gov/briefing-room/statements-releases/2021/03/26/president-biden-invites-40-world-leaders-to-leaders-summit-on-climate/

[3] “Conservatively valued at US $57 Billion”: http://ewastemonitor.info/

[4] https://www.overshootday.org/

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.