The ongoing supply chain disruptions that started in 2020 are expected to continue into 2022 and beyond. COVID-19 may have been the trigger, but the problems were already looming. Customer buying behavior is changing, many systems are still manual, supply channels are under stress and the drive for cost savings is always present.

Where are the most common problems?

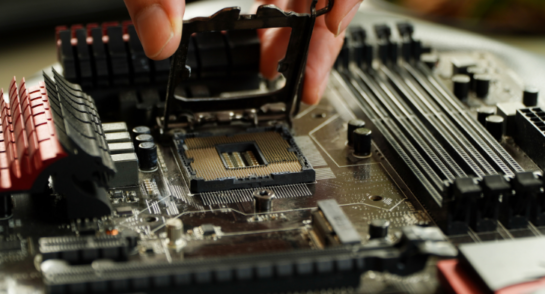

Current supply challenges include the shortage of computer chips, shipping containers and limited port capacity. These are directly impacting service supply chains through higher prices and transport delays. Slow and uncertain delivery dates lead to the growth of expensive buffer stocks and underutilized assets.

Supply chains lack the required agility because the implementation of suitable technologies to streamline operations has been slow. Effective decision-making depends on supplier and transaction data that is visible, reliable, and available in real-time. Many supply chain processes still depend on paper-based systems, and this must change.

In many supply chains, there is a lack of internal coordination and cooperation, leading to a silo-mentality where decisions are made in isolation. Cost savings are hard to achieve where there is no clear central purchasing strategy. Additionally, there is the sustainability issue – external stakeholders (shareholders, investors, and customers) are putting pressure on organizations to achieve Environmental, Social, and Governance (ESG) goals and to invest in greener solutions.

How to address the problems

Cost reduction

Not all cost savings are achieved through price negotiation with key suppliers. There are process improvements where money can be saved by reducing

- unnecessary or repetitive customer touchpoints including calls and truck rolls

- the turn-around time for equipment repair and redeployment

- excess spend on new customer premise equipment (CPE)

- no fault found (NFF) returns

- transport and storage costs, and handling fees from third-party logistics (3PL) providers

- wasteful packaging in both delivery and returns

Developing resilience and flexibility

Building resilience allows you to react and respond to changing conditions early to avoid expensive and potentially disastrous disruptions. The current chip and resin shortage issues have highlighted the need for market awareness, better planning, coordinated delivery, and focused recovery. Anticipating demand and being aware of market fluctuations as early as possible means that you can respond and adapt accordingly. For example, by proactively identifying the end-of-life date for CPE, you can design and implement a plan to efficiently manage replacement efforts.

The adoption of “lean” processes over time has had many advantages but may have had a detrimental effect on resilience in your supply chain. Operating with minimum safety stock and relying on just-in-time inventory solutions has brought more risk and less flexibility. It is a delicate balance. Building strong key supplier relationships in times of disruption is vital to avoid stockouts; reliance on single-source suppliers is risky. Incorporating a level of flexibility into the supply chain allows a quick adjustment to changing market conditions. Real-time data is needed to be able to plan (and change plans).

Data visibility

Visibility across the whole network is the cornerstone of effective equipment and parts management within the service supply chain. Rapid advancements in digital solutions for supply chain can now provide timely, accurate, and comprehensive information that provides actionable insights which allow you to effectively manage your business. It’s about aggregating and analyzing the data, then converting it into usable information. The key to success is gathering, verifying and enriching the data information with additional market intelligence. There must be one instance (a source of truth) only that should be shared consistently across the enterprise. End-to-end supply chain visibility is the goal – this includes suppliers and customers.

Digitization

Digitization provides a way to accumulate discrete pieces of data that, when combined and enriched, can be made available and transparent cross-functionally within an organization, and also with end-customers! Sharing reliable, real-time information with internal and external users in the supply chain through multiple communication channels has been shown to drive better business outcomes, and a drastically improved customer experience.

Advancements in cloud-based software solutions have been a game-changer. Technologies using tools such as 5G, AI, robotics, the Internet of Things (IoT) and data analytics are becoming affordable and easier to use. Data is combined and made available in real-time across the organization, not trapped in silos. In this way, information becomes an active means of cross-functional communication.

Sustainability

Companies in the service supply chain may also use reverse logistics to support environmental, social and corporate governance (ESG) initiatives. The opportunity exists to extend the life of assets, prevent unnecessary waste, reduce carbon emissions and avoid adding to landfills. The focus should be on responsible and sustainable practices such as refurbishment programs and the recovery of reusable items. A circular service supply chain encourages manufacturers and distributors of products to recover used and discarded products and materials for eventual reuse.

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.