Traditional manufacturing supply chains based on the principle of make-use-discard, that have historically served the marketplace well, are no longer sustainable. Circular service supply chains are developing the return and refurbishment of one-time-use products and end-of-life items for their reuse. There are two main reasons why this is happening; businesses are challenged with a) the scarcity of raw materials and related price volatility and b) the pressure to reduce waste and become more environmentally sensitive.

The circular supply chain

A circular service supply chain encourages manufacturers and distributors of products to recover used and discarded products and materials for eventual reuse. It is often assumed that the expense involved in investing in the recovery of parts is prohibitive. Not so, once processes are in place, the cost of raw materials is less, supplier risk and price variations are contained, and environmental targets are attainable. The recovery of parts also reduces the need for new-buys, which lowers cap-ex for the companies.

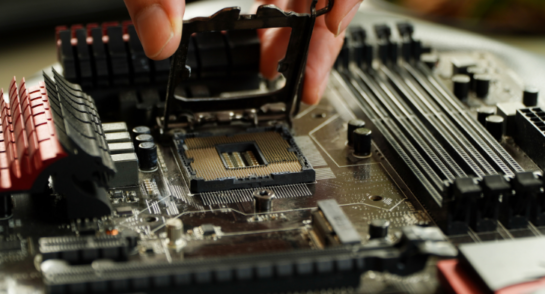

Many of the world’s leading technology, medical device, wireless, broadband, manufacturing, and consumer electronics companies have committed to a more regenerative society. They want to “close the loop”. Instead of disposing of products at the end of their lifecycle, they can deliver as-new products to the marketplace by recovering and repurposing components. A key aim is to become more environmentally responsible by creating longer product lifecycles and lowering the damage created by unmanaged product disposals.

Consumer pressure

Businesses are under pressure to adopt a circular supply chain model from government, investors and consumers. Nielsen, the market research company, reports that 66% of global customers surveyed are willing to pay more for sustainable goods. Customers are looking for:

- Sustainable products that are biodegradable, environmentally sustainable, and ethically sourced

- Manufacturing processes that strive for zero waste and impact the environment minimally while increasing health and safety numbers

- Logistics processes that optimize loads to reduce mileage, emissions, and carbon footprint

- Assets that are designed and operated in an energy-efficient manner and are safe for the environment and workforce

Compliance with regulations on recycling and waste disposal are also driving forces in the growth of circular supply chains.

Finding solutions in data

OEMs (original equipment manufacturers) of consumer electronics, storage, and networking hardware continuously strive to improve the customer experience while reducing costs. These problems are felt across other industries with a similar business model, e.g., telecommunications, and medical equipment. Optimizing the forward and return service supply chain in these businesses is challenging, there are high inventory costs, penalties for late delivery of services, slow and complex logistics and onerous administration. Visibility into the activities in the supply chain is often limited due to systems and software that are not compatible or integrated. Outsource partners with expertise in circular supply chain management have technology tools that create visibility into the volumes of data generated by organizations. Data, when converted into information, is used to make critical decisions.

The Product-as-a-service model

Product as a service is the concept of selling the services and outcomes that a product can provide, rather than the product itself. Signify (formerly Philips Lighting), are taking control of their product throughout its lifespan. The company provides lighting services that include the assessing of your current system, the provision of a lighting plan and implementing a solution, hassle-free maintenance, remote support and guaranteed lighting performance. The objective is to provide the customer with a one-stop streamlined service while also reducing energy costs. This is also one way to ensure that their products do not end up in landfills.

However, delivering such a model requires a greater focus on keeping the product (or rather the service) running, which in turn means an increased focus on service, repair and maintenance. The As-a-service model requires that:

- Inventory of replacement parts for repairs and maintenance are held in the right place to meet Service Level Agreements (SLA) commitments

- Service parts are delivered at the right time against SLAs

- As much value as possible is recovered from the parts n longer needed in field (old parts, unused new parts etc)

OnProcess Agora™: The Dynamic Service Insight platform

We’ve built a platform, called OnProcess Agora, that generates and applies Dynamic Service Insight. Agora allows us to capture both part and customer data from across the post-sales lifecycle. Then, we combine this information with our own datasets, before organizing and structuring it to generate Dynamic Service Insight. Finally, we apply this insight to automate and streamline processes on behalf of our customers.

Agora Recover is the recovery module of this platform. It optimizes the asset recovery process – facilitating, tracking and expediting the return of assets from the field or customer. In turn, this helps to dramatically reduce costs while improving customer experience. It’s a truly circular process, for a truly circular economy.

We partner with our clients to optimize their service supply chain management processes. We deliver end-to-end service visibility and insights that break down the silos that exist in current service supply chains. We work with our clients to drive cost savings and revenue growth while supporting a superior vendor and customer experience. We achieve this with a firm focus on applying advanced analytics and industry-leading best practices to drive success.

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.